Glass Railing Hardware

Glass Railing Hardware

Handrail System

Handrail System

Pool Fence Hardware

Pool Fence Hardware

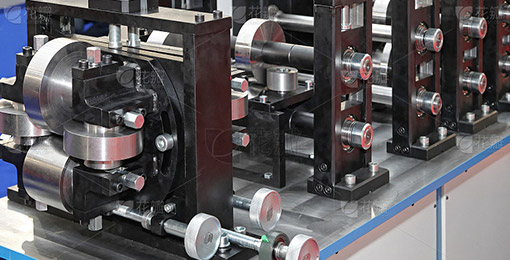

Explore our range of cutting-edge machines for customized product manufacturing. These advanced machines combine precision, efficiency, and versatility to deliver results.

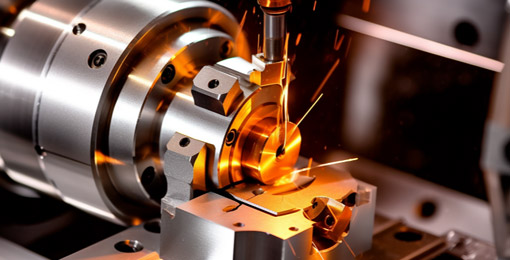

With high precision and automation, CNC machine ensure accurate cuts, intricate designs, and efficient production, resulting in perfectly tailored glass components.

With high precision and automation, CNC machine ensure accurate cuts, intricate designs, and efficient production, resulting in perfectly tailored glass components.

CNC machines offer easy adaptation and customization of production processes. We can swiftly adjust settings and programming to accommodate various designs, sizes, and materials, providing you with a wide range of options.

Leveraging the efficiency of CNC machines allows us to provide competitively priced customized shower enclosure accessories. The streamlined manufacturing process reduces production costs.

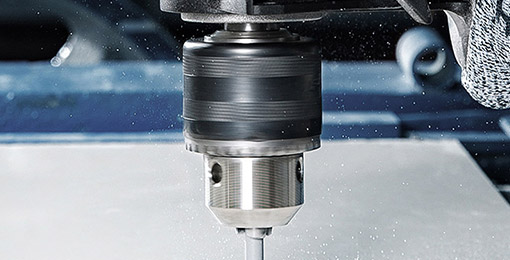

Laser machines offer high-speed cutting capabilities, resulting in efficient production and reduced turnaround times. The versatility of laser cutting technology allows for customization of shapes and sizes, providing greater flexibility.

The laser machine ensures impeccable edge quality and smooth finishes, resulting in high-quality and visually appealing shower enclosure accessories, staircase fittings, and glass door handles. Precise control of the laser beam minimizes errors, ensuring consistent and aesthetically pleasing products.

Laser machines operate at high speeds, enabling efficient production of a large volume of products in a shorter timeframe. This increases productivity, reduces lead times, and ensures timely delivery without compromising on quality.

With a laser machine, we offer extensive customization options, allowing customers to have unique designs, logos, or text engraved or cut onto their shower enclosure accessories, staircase fittings, or glass door handles. This adds a personalized touch to their spaces.

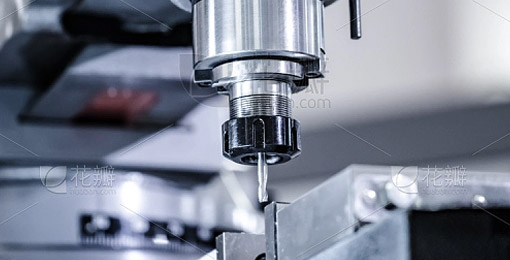

With automation, automatic drilling machine provides reliable and repeatable results, minimizing errors and improving product quality.

The automated drilling process ensures consistent hole placement and depth in multiple products, ensuring uniformity and high-quality standards. This guarantees that our shower enclosure accessories, staircase fittings, and glass door handles meet required specifications and exceed you expectations in terms of durability and functionality.

The automatic drilling machine improves production efficiency and productivity by automating the drilling process. This reduces manual labor, and enables us to meet you demands efficiently within shorter lead times.

The automatic drilling machine ensures precise and accurate drilling of holes consistently. With advanced positioning systems and programmable settings, it eliminates human errors and ensures perfect alignment for a seamless fit.

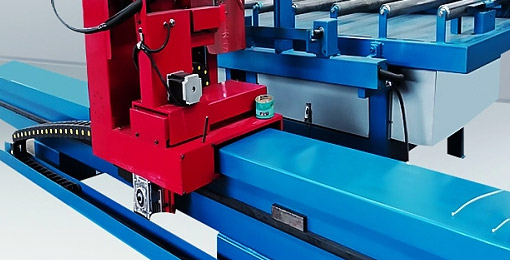

This machine enables us to create robust and durable products with enhanced structural integrity and strength, ensuring long-lasting performance.

The controlled forging process eliminates defects inconsistencies, resulting in components that meet stringent quality standards. This enhances the overall performance and longevity of glass shower enclosure accessories, staircase fittings, and commercial glass door accessories.

The 400-ton forging machine creates robust and durable products by applying immense pressure during the forging process. This enhances the structural integrity and strength of the components, ensuring they can withstand heavy-duty use and provide long-lasting performance.

With the 400-ton forging machine,it enables us to forge intricate shapes, unique patterns, and personalized details that cater to the individual needs and preferences of our customers.

We have advanced product testing equipment.This ensures precise and thorough testing, resulting in high-quality products that meet stringent standards.

This test evaluates the ability of the glass hardware components to withstand corrosion when exposed to wet and water-contact environments, ensuring their long-term durability.

This test examines the sealing effectiveness of the glass hardware components, including the integrity of connections and water resistance, ensuring effective prevention of water leakage and moisture penetration during use.

By subjecting the products to a simulated salt spray environment, the extent of corrosion observed and recorded helps determine the durability and reliability of the products in corrosive conditions.

Looking for high-quality glass accessories? We offer a wide range of standard and customizable parts. Contact us today by filling out the form below and let us assist you in finding the perfect solution!